And for machined components iso 2768 fh can be used.

Sheet metal flatness tolerance.

Sheet metal guage tolerances.

During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

Flatness tolerances for sheet are published only for full size sheets.

Only short span flatness tolerance applies short span flatness 5 tolerance 6 in.

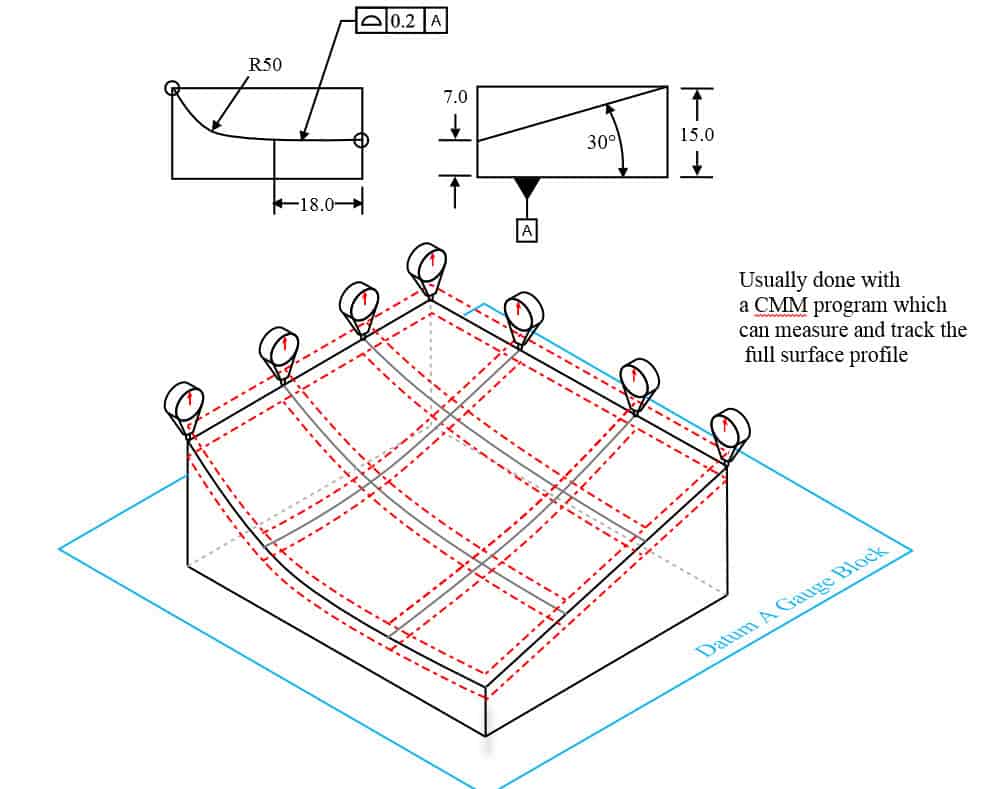

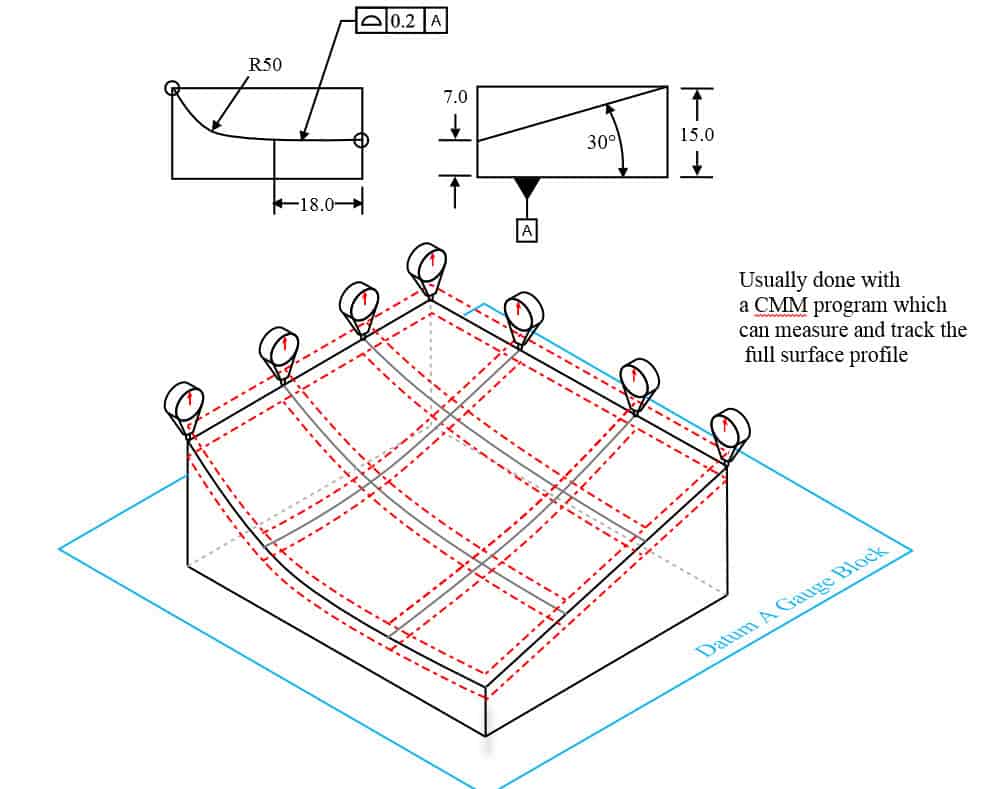

When applied to a surface of a part the flatness must always be less than the dimensional tolerance.

For material 10 or less in length variation should not exceed amount shown in table.

This not only control the rock but also the allowable mechanical stress which deform the shape of the sheet metal like in case of parts that will be welded thermal stress bolted bending due to too much torque or screwed.

Flatness tolerances listed are of roller leveled sheets or plates with no or minimum margins.

Practical tolerances vary according to the design requirements.

For sheet metal parts iso 2768 mk is used.

Tolerance class is defined as per design requirements and manufacturing capability.

Flatness application sheet metal.

Tolerances of 010 should be considered minimum.

For material longer than 10 the variation in flatness for any 10 feet of length should not exceed the amount shown.

Flatness is a form control.

In general sheets 60 wide and under are to be no more than out of flat when laid on a flat surface.

Perfect flatness is when all points of a surface lie in the same plane.

Flatness can be applied to an entire feature in the case of a sheet metal plate or to just the surface of a part.

Plates can be out of flat for a number of reasons.

Sheet metal is often controlled with flatness tolerance.

Since rolled alloys also levels this product we work to the mill tolerances.

Linear tolerances should be held as loose as possible.

The resulting bend angle variation and sometimes the required adjustment to the flat layout contributes to the reason that machined parts typical tolerance of 0 002 in can routinely have tighter tolerances than precision sheet metal parts typical tolerance of 0 010 in.

Allowable deviation from flat tx51 tempers 2 aluminum technical data sheet and plate flatness tolerances flatness tolerances flat sheet 1 alloy includes alclads specified thickness in.

Sheet metal tolerances should not be tighter than necessary to make the part functional.

Tight tolerances raise the cost of manufacturing significantly.

1989 general tolerances part 2.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances.