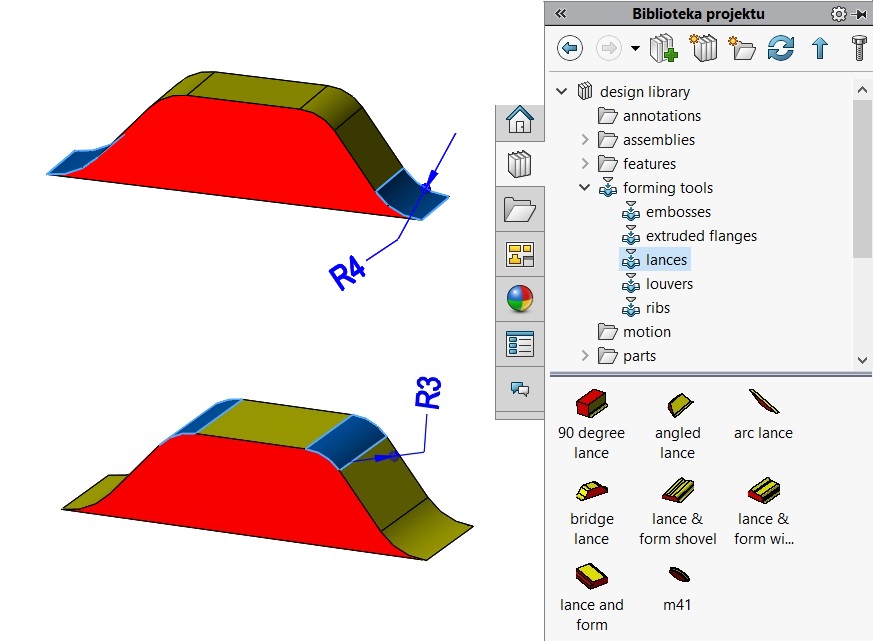

Design hub in this tutorial video i will show you how to use forming tool in sheet metal in this video you lean forming tool as well sheet metal bonet with.

Solidworks sheet metal knockout.

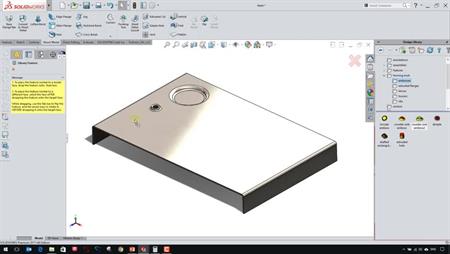

In this tutorial video i will show you how to sketch a box in solidworks with the help of sketch and sheet metal tools.

When creating custom forming tools be careful not to create any curved.

Sheet metal hole knock outs madmango.

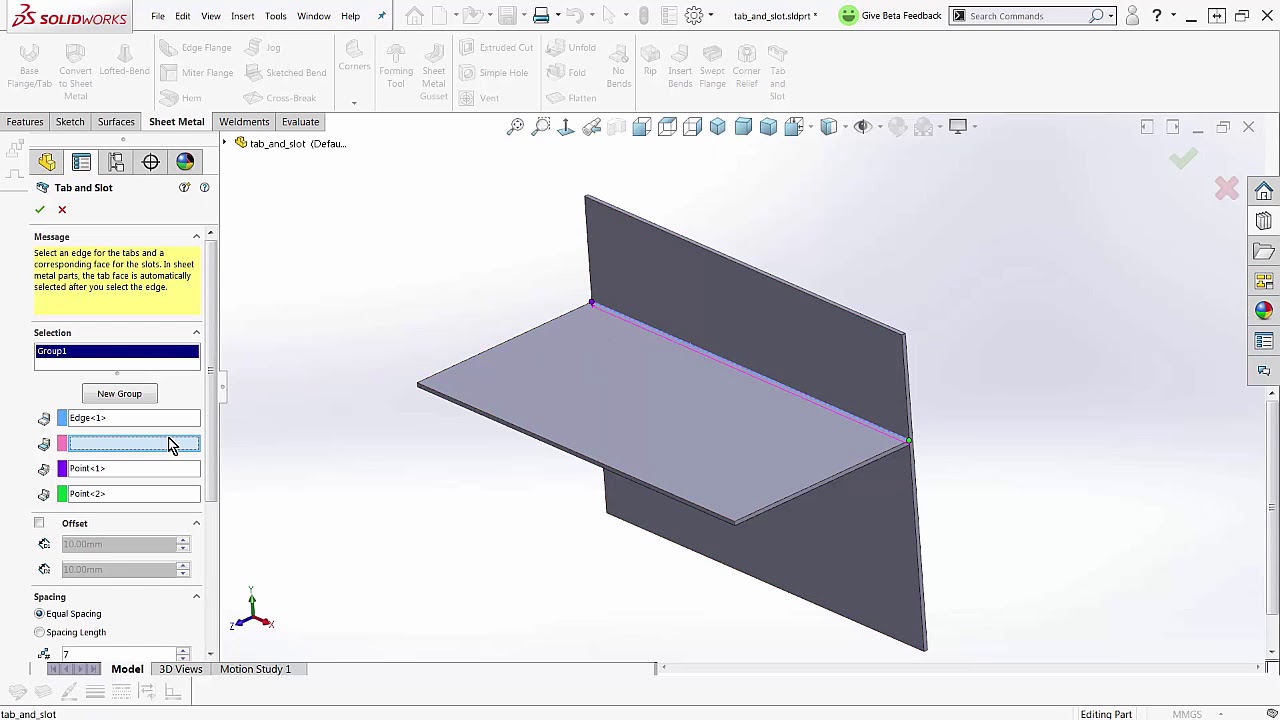

We can use these features to create sheet metal designs with several different methods.

In my previous blog forming tools we examined how pre solidworks 2006 sheet metal forming tools differ from those which can be created today.

We will focus on the flange method where a sheet metal part is created in the formed state using specialized sheet metal features.

If you do sheet metal in house you can go the laser cut route.

Solidworks 05 sp1 1 pdmworks 05 ctopher s home site.

We use a portable knockout punch set and i would only create the center hole and the guy that completes the panel would complete the knockout i feel you need to know how it will be completed now if you just want to show the completed feature in a model than use the sheet metal punch forming tool.

Sheet metal parts display the sheet metal feature in the featuremanager design tree.

We examined how to save forming tools as form tool part files and what the advantages were of doing so.

There are specific sheet metal features you can use to create sheet metal bodies quickly.

In this tutorial video we will learn how to make forming tool with the help of sheet metal tool and create a forming plate with the help of forming tool.

Solidworks 3d allows you to quickly create sheet metal part designs using a simple design process saving you time and development costs thanks to specific sheet metal features.

You might also like.

If these parts are going out to vendors you really don t want to define the manufacturing process unless laser cutting is a quality requirement of the part.

1 solidworks tutorial for be.

Please subscribe our channel for more.

However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.