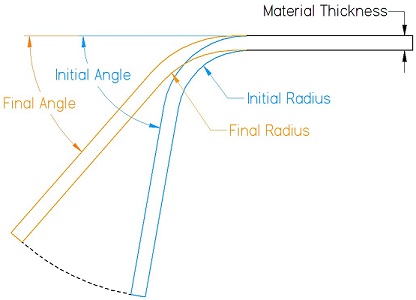

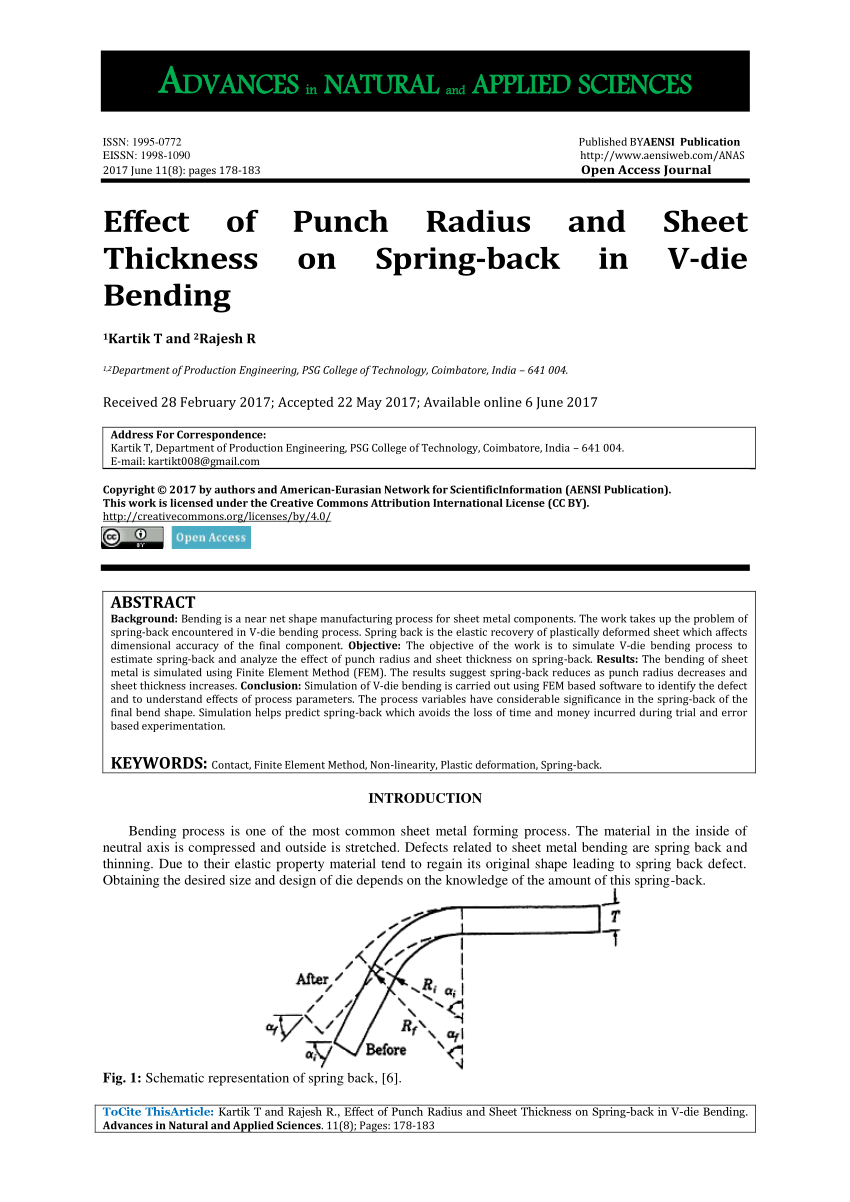

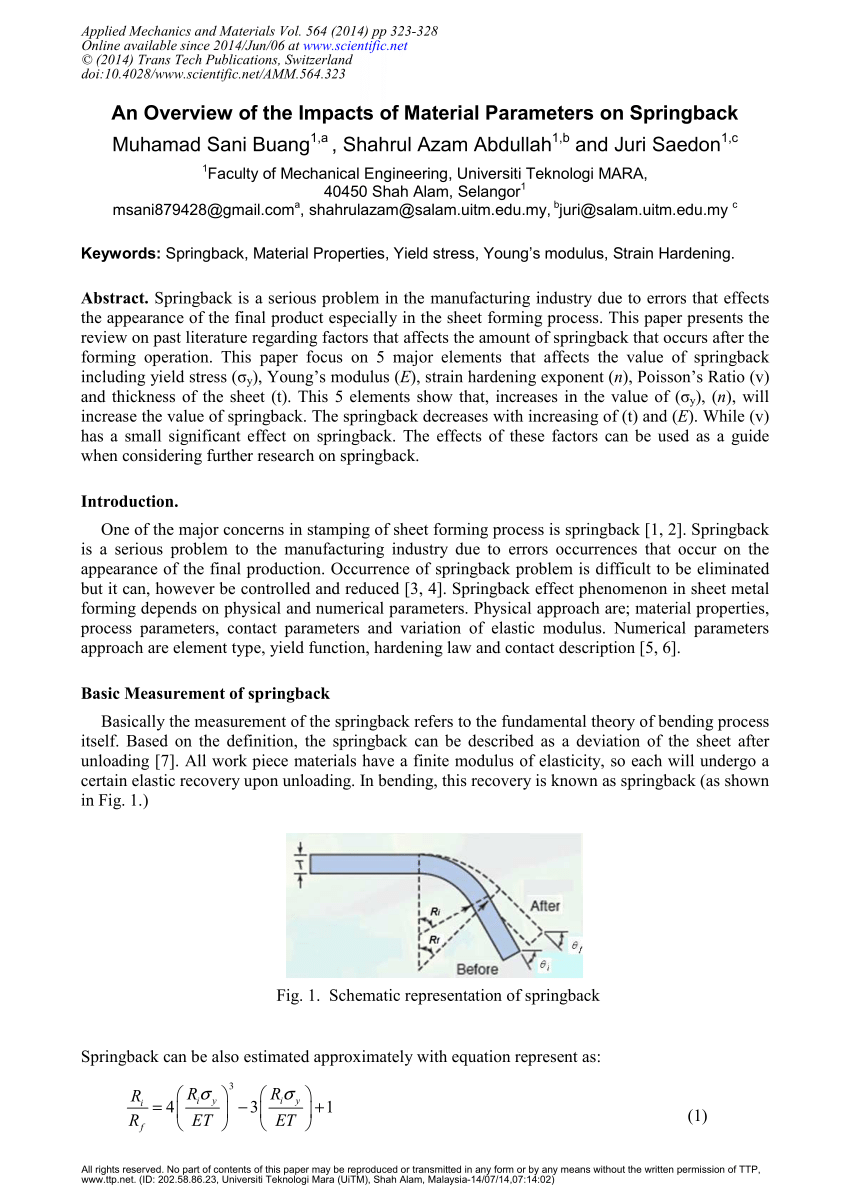

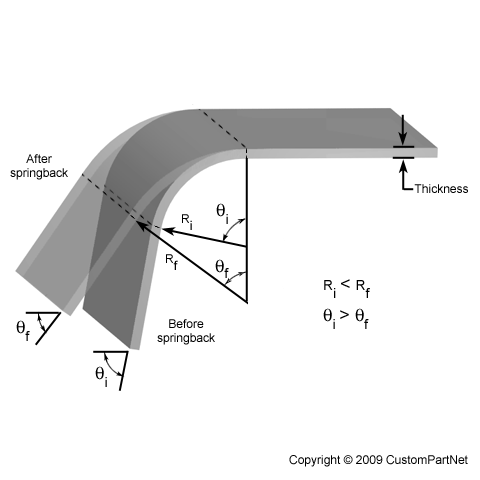

This phenomenon is known as springback when applied to angle change and as the springback factor sf applied to the radius.

Springback phenomenon in sheet metal forming.

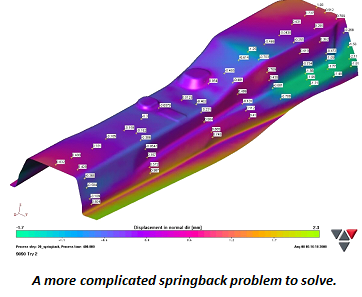

Obtained in a numerical simulation of springback is essential for the product designers and die makers.

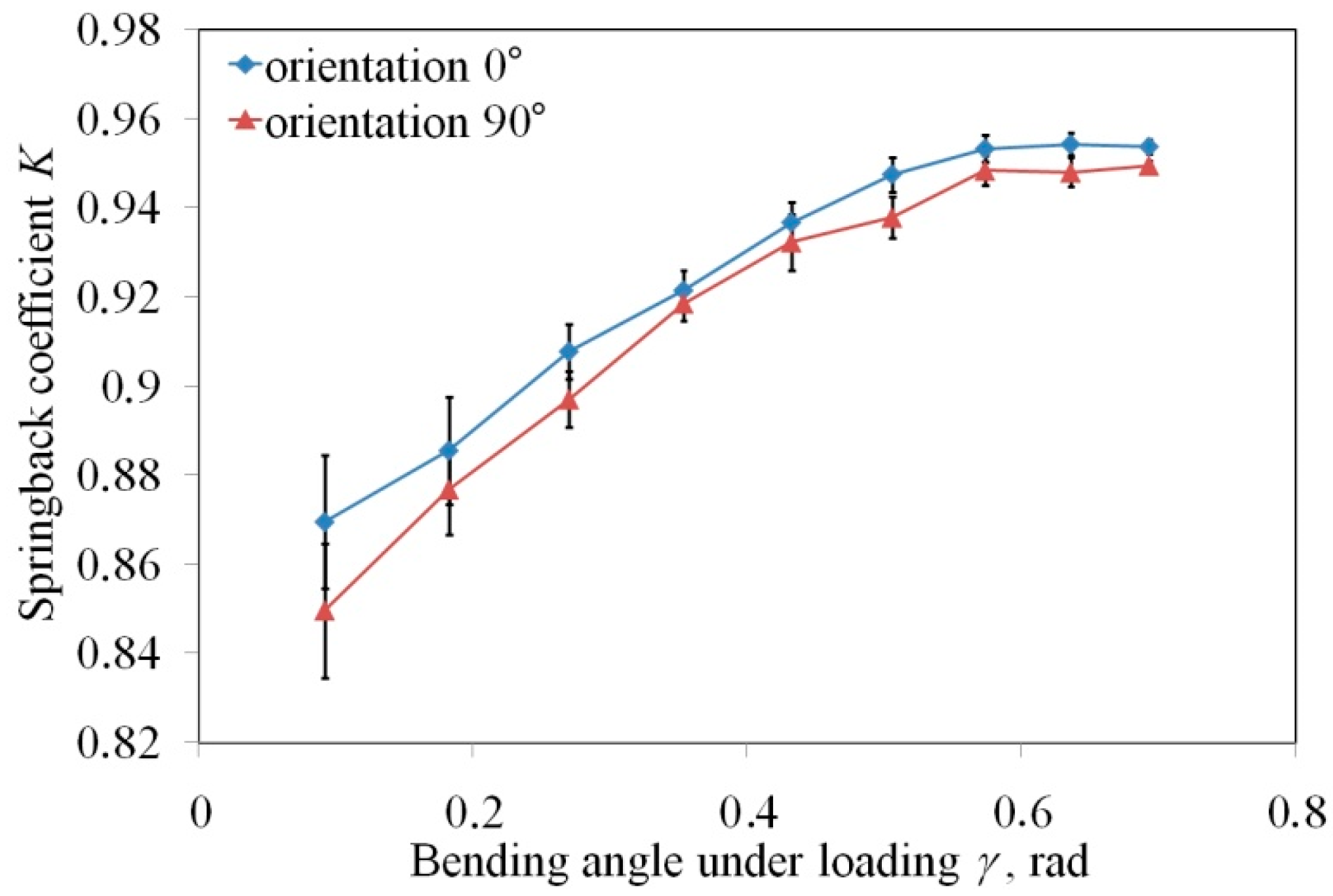

The amount of springback that occurs is a property of the material and radius.

This thesis deals with the improvement of numerical prediction of the springback phenomenon in sheet metal forming.

Bending springback calculator after a bending operation residual stresses will cause the sheet metal to spring back slightly.

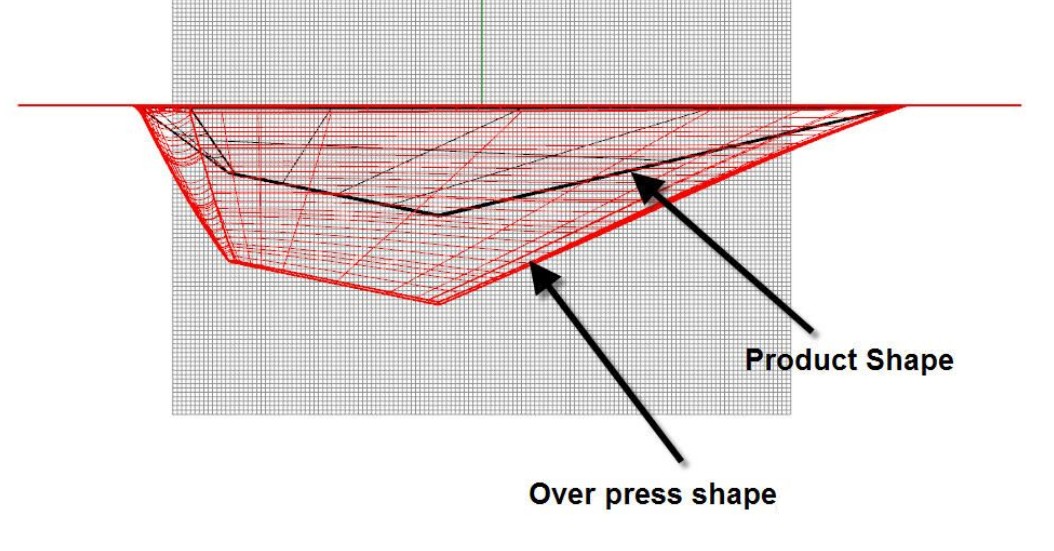

Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle.

The inside radius also relaxes getting larger which in turn affects the numbers for bend allowance ba outside setback ossb and bend deduction bd.

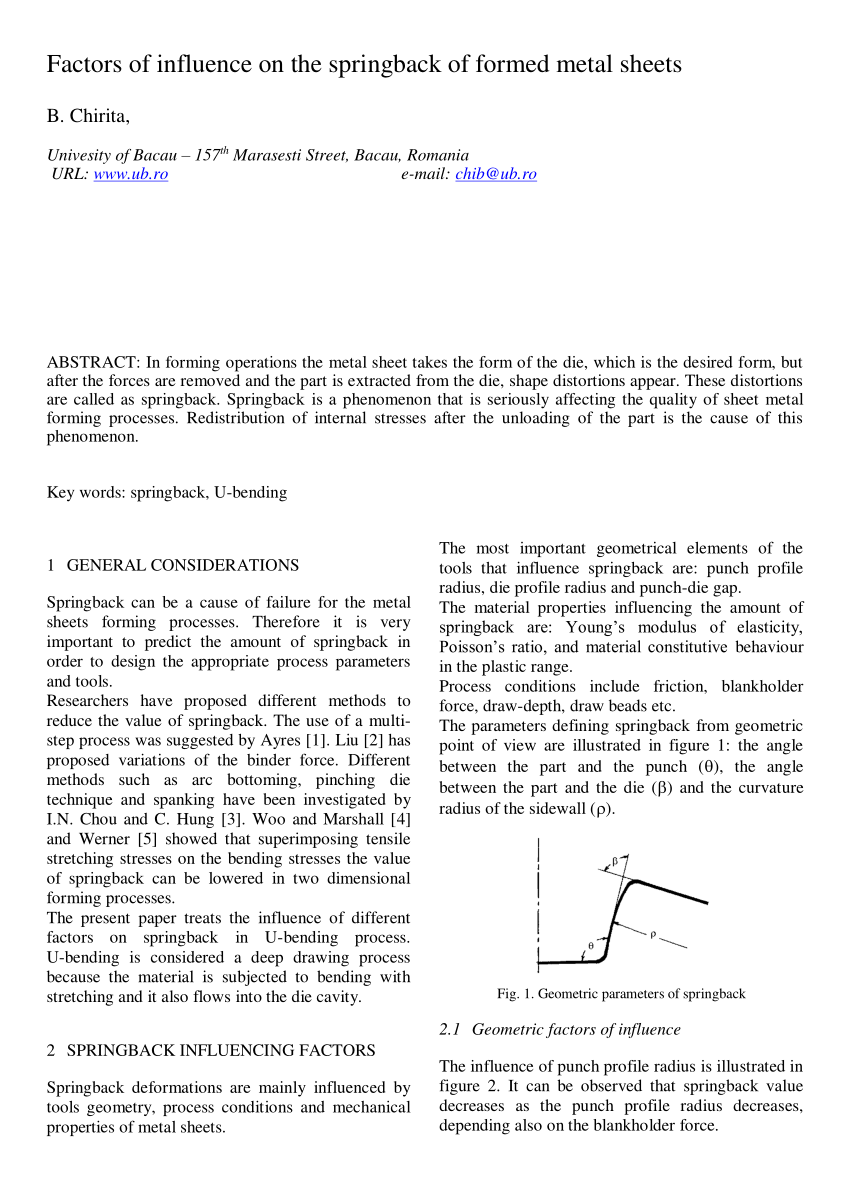

At the end of the forming process when the part has been released from the forces of the forming tool there is a distortion in the shape and dimension of the formed part.

Spring back sheet metal forming 1.

Springback and forming method.

The air forming zone shows that when the press brake exerts pressure on the sheet the metal begins to bend.

This sheet metal forming device and process reduces or eliminates springback.

Springback is a common phenomenon that occurs in sheet metal forming when metal is bent but then springs partially back toward its original shape thus requiring corrections to be made.

Springback is inherent in sheet metal forming.

Springback is the deformation that will inevitably occur after the sheet metal is formed and the forming part is removed from the mold which will affect the final shape of the part.

Modelling guidelines and advanced numerical algorithms are presented that better satisfy industrial requirements for an accurate.

Springback is the geometric change made to a part at the end of the forming process when the part has been released from the forces of the forming tool.

The springback value will directly affect the geometric precision of the workpiece which is also a forming defect that is difficult to overcome in the technique.

This distortion is termed springback.

Upon completion of sheet metal forming deep drawn and stretch drawn parts spring back and thereby affect the dimensional accuracy of a finished part.

Introduction the sheet metal forming process involves a combination of elastic plastic bending and stretch deformation of the workpiece.

These deformations may lead to a large amount of springback of the formed part.

Die design optimization on sheet metal forming with considering the phenomenon of springback to improve product quality article pdf available in matec web of conferences 154 7 01105 january.

The device is a die tool and roller that rotates relative to the die during and or.