Bend relief and collars near pierced areas strengthen sheet metal parts.

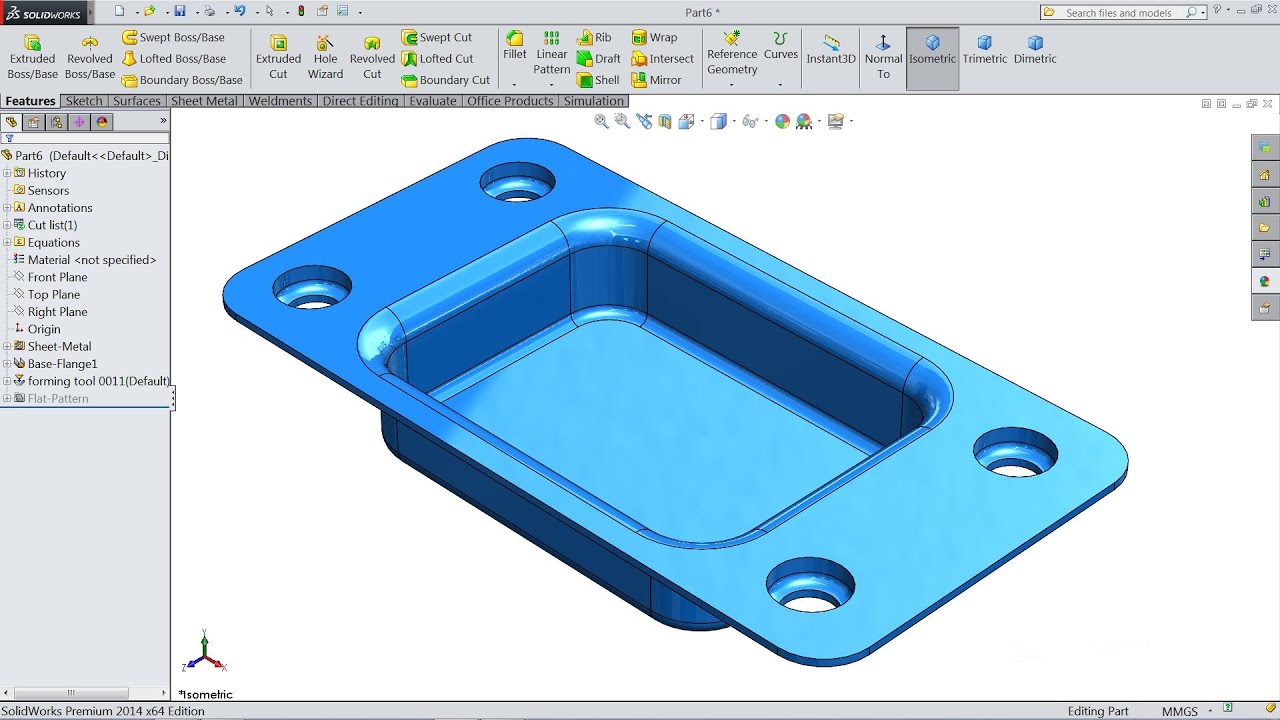

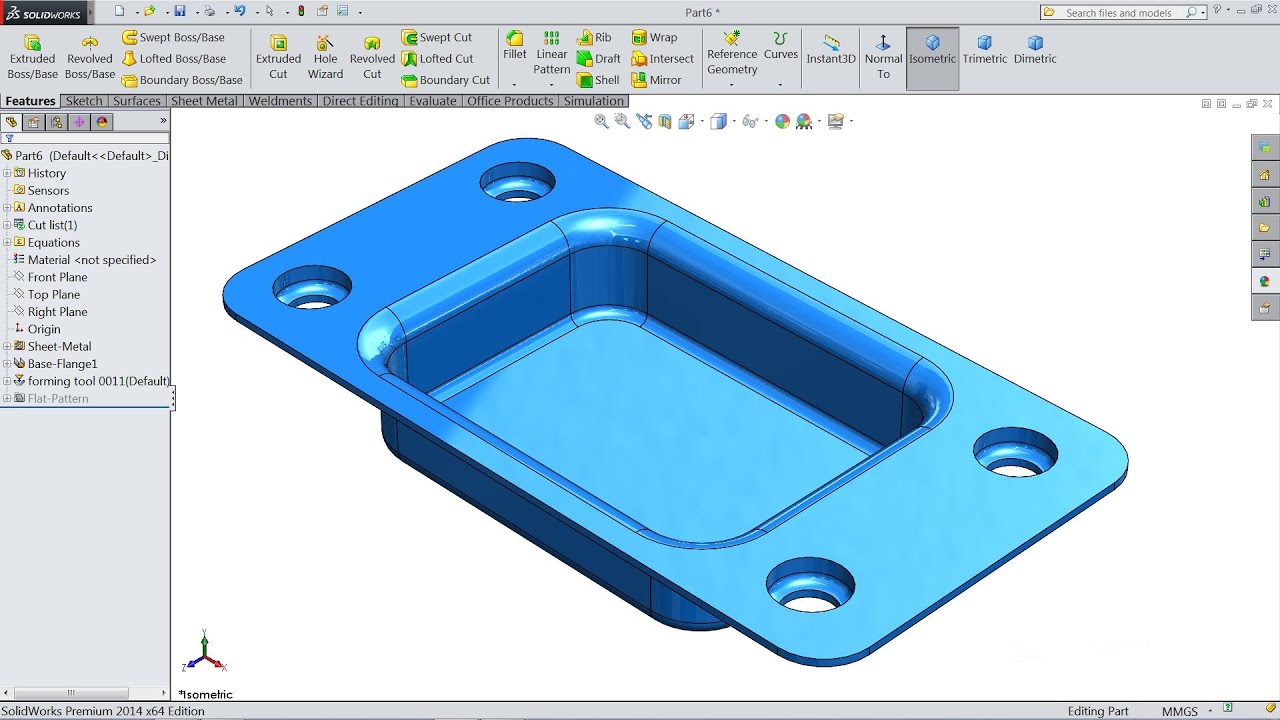

Strengthening sheet metal parts.

As the material is deformed the effective material thickness increases and the material becomes stronger.

Or two times the material thickness across whichever is greater.

Sheet metal is a processing technology and has not yet had a relatively complete definition.

In sheet metal fabrication parts are formed from metal sheets by punching cutting stamping and bending.

These should be one material thick or wider and extend no more than five times the slot width into the workpiece.

One such function is to add strengthening ribs.

Sheet metal parts often require notches to accommodate a screw or other fastener.

Bead rollers are one of the versatile metal working tools ever produced.

Knowing techniques for how to roll sheet metal edges and create grooves in a panel are important for fabricating new body panels on a restoration project.

According to a definition in a professional journal it can be defined as.

Sheet metal should be bent at the minimum bend radius possible.

The truth is that sheet metal can actually be very strong once we modify and strengthen it.

These metal beads are used for decorative purposes and in hvac equipment.

The metal in the areas where holes and slots are punched gets stretched and become more tensile which gives more structural rigidity to the sheet metal.

In this tech guide we re going to cover some of the ways you can modify a piece of sheet metal.

It is used to join different material and sheet thickness parts.

These equipment are used for strengthening or shaping metal sheets and fabricating beads.

Woodward fab offers industry grade metal bead rollers which enable efficient sheet metal bending operations.

Another way of strengthening the sheet metal is by punching holes and slots.

Grain structure in the metal sheet is critical for avoiding cracks in sheet metal parts with lugs or tabs that are cut on.

Sheet metal clinching joint creates a button type positive connection between two or three layers of sheet metal.

Being a sheet metal designer it is important to have a set of goals and design strategies defined when developing a sheet metal product to ensure that the product is cost effective as well as feasible to manufacture.

Clinching joint is a type of permanent sheet metal joining operation that involves joining sheet metal parts using cold forming operation.

Embossing operations are commonly used in sheet metal and vary in purpose and function.

3d cad files are created using a host of different cad packages and then converted into.

Similarly the tabs on either side of a notched feature should be at least 0 126 in.