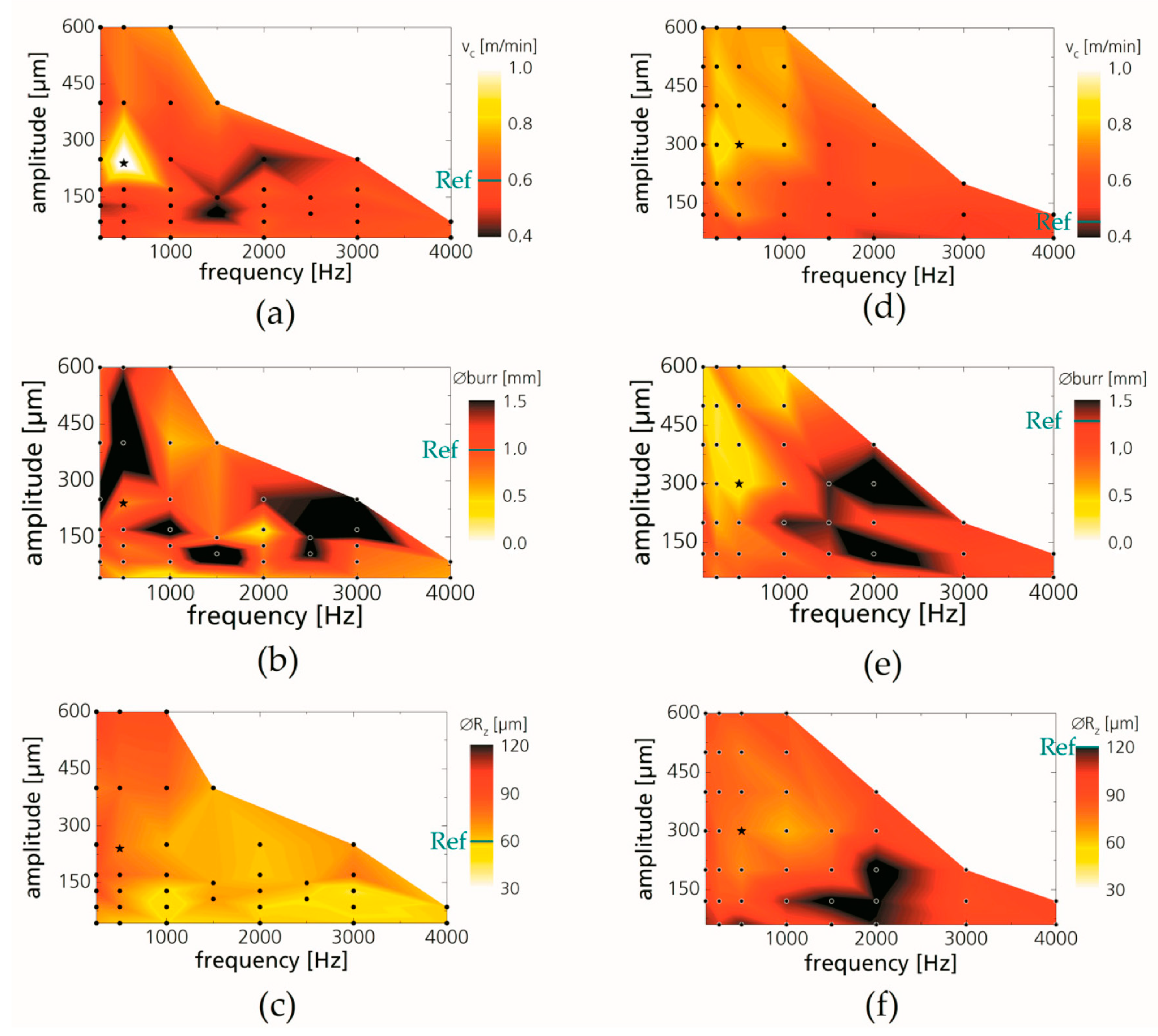

The optimal operating windows are presented and a mathematical method is proposed to estimate the critical speed at which striation free cut can be obtained.

Striation free laser cutting of mild steel sheets.

Figure 5 shows the operating windows where striation free laser cutting can be achieved.

Striation free laser cuts are demonstrated when cutting 1 mm thick mild steel sheets.

Striation free laser cuts are demonstrated when cutting 1mm thick mild steel sheets.

Striation free laser cutting of mild steel sheets.

Striation free laser cuts are demonstrated for cutting 1 and 2 mm thick mild steel sheets.

Some figures in this article are in colour only in the.

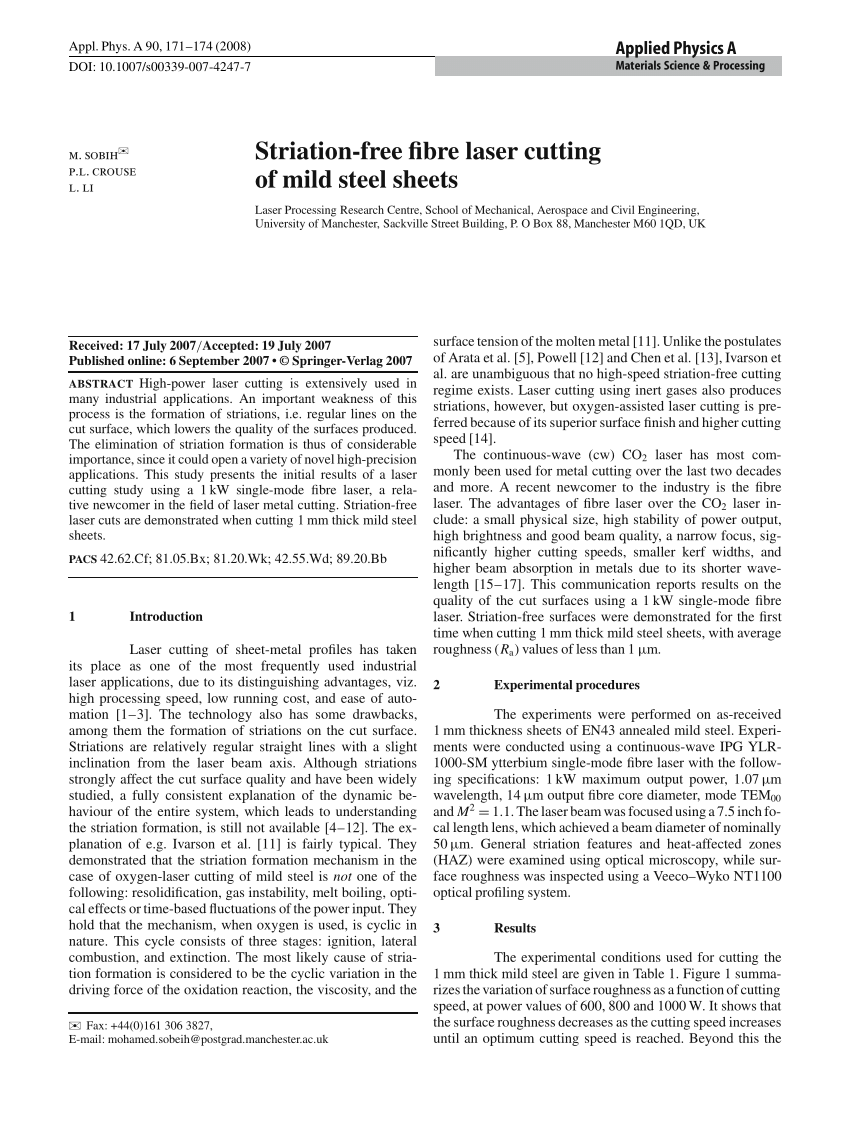

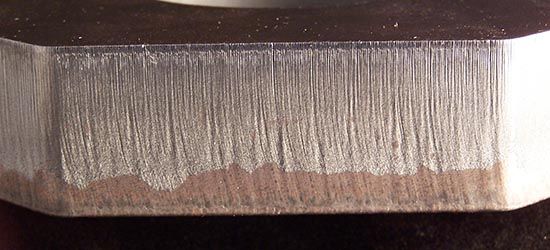

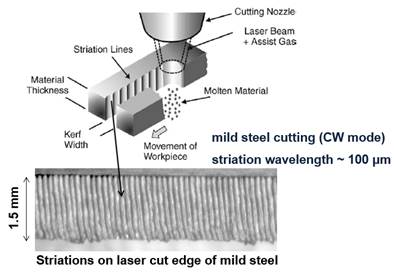

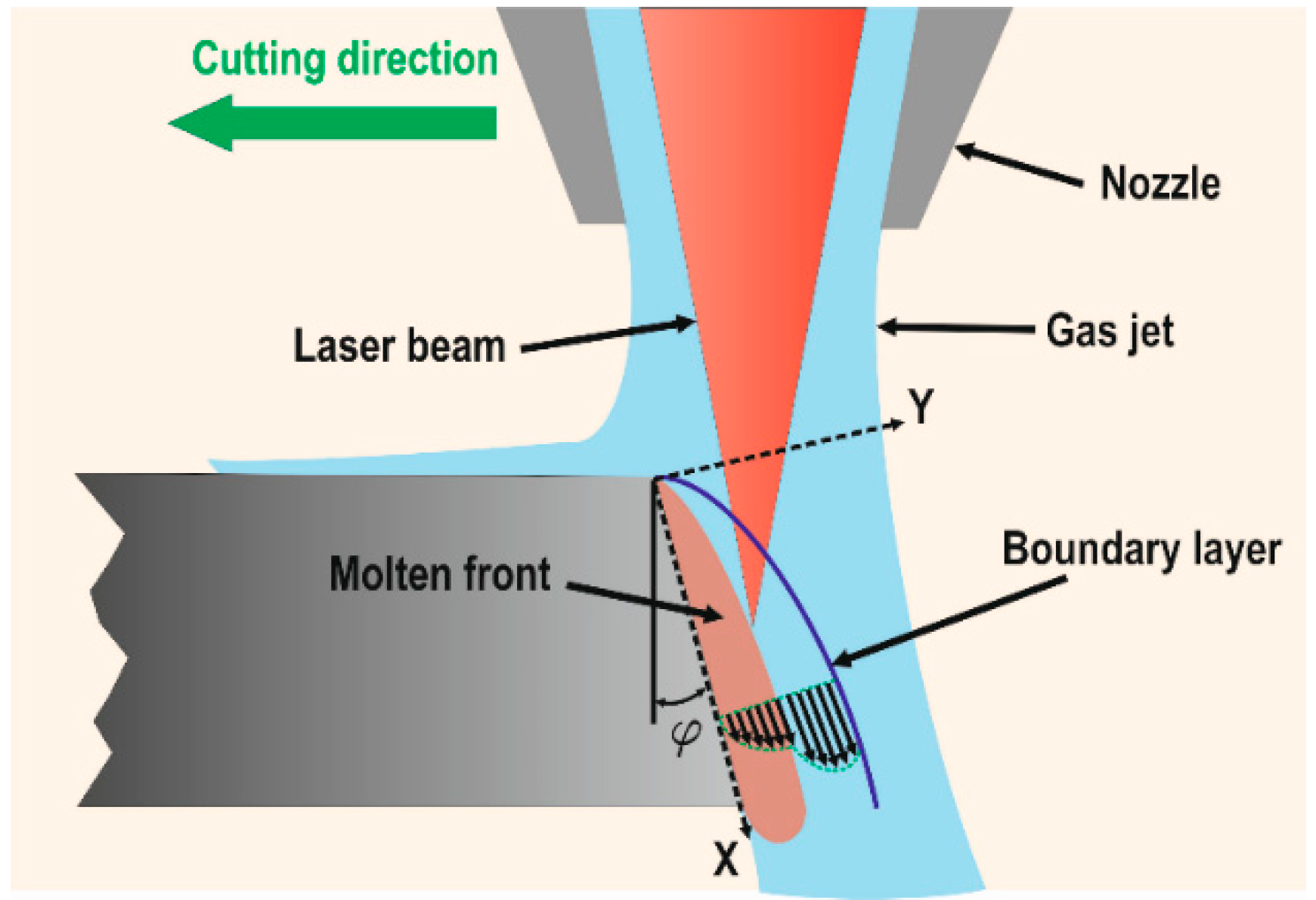

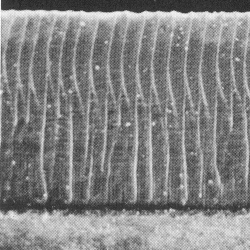

Regular lines on the cut surface which lowers the quality of the surfaces produced.

Sheets using a high power fibre laser.

Striation free laser cuts are demonstrated for cutting 1 and 2mm thick mild steel sheets.

The optimal operating windows are presented and a mathematical method is proposed to estimate the critical speed at which striation free cut can be obtained.

Higher laser power allows higher cutting speed and the entering into the striation free cut zone.

Striation free cut of the 2 mm thick mild steel cannot be achieved with a laser power below 600 w.

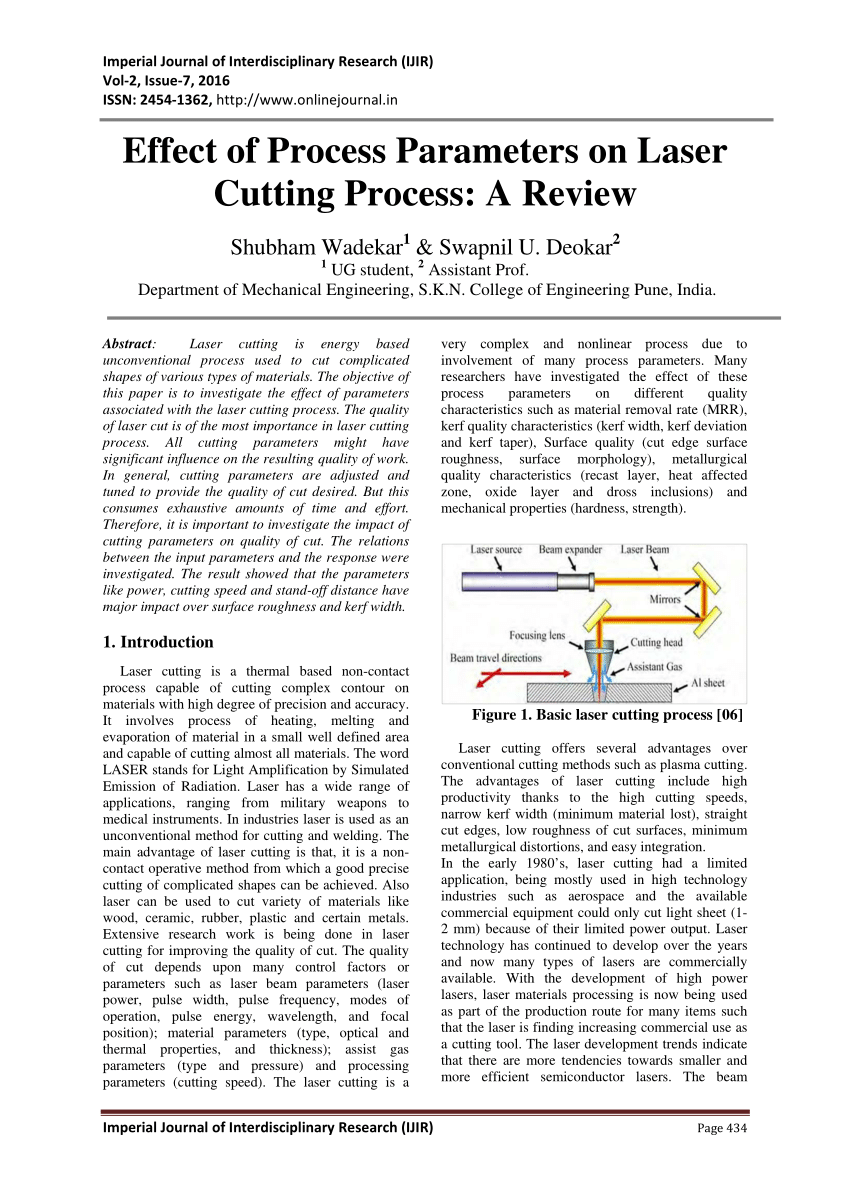

This study presents the initial results of a laser cutting study using a 1 kw single mode fibre laser a relative newcomer in the field of laser metal cutting.

High power laser cutting is extensively used in many industrial applications.

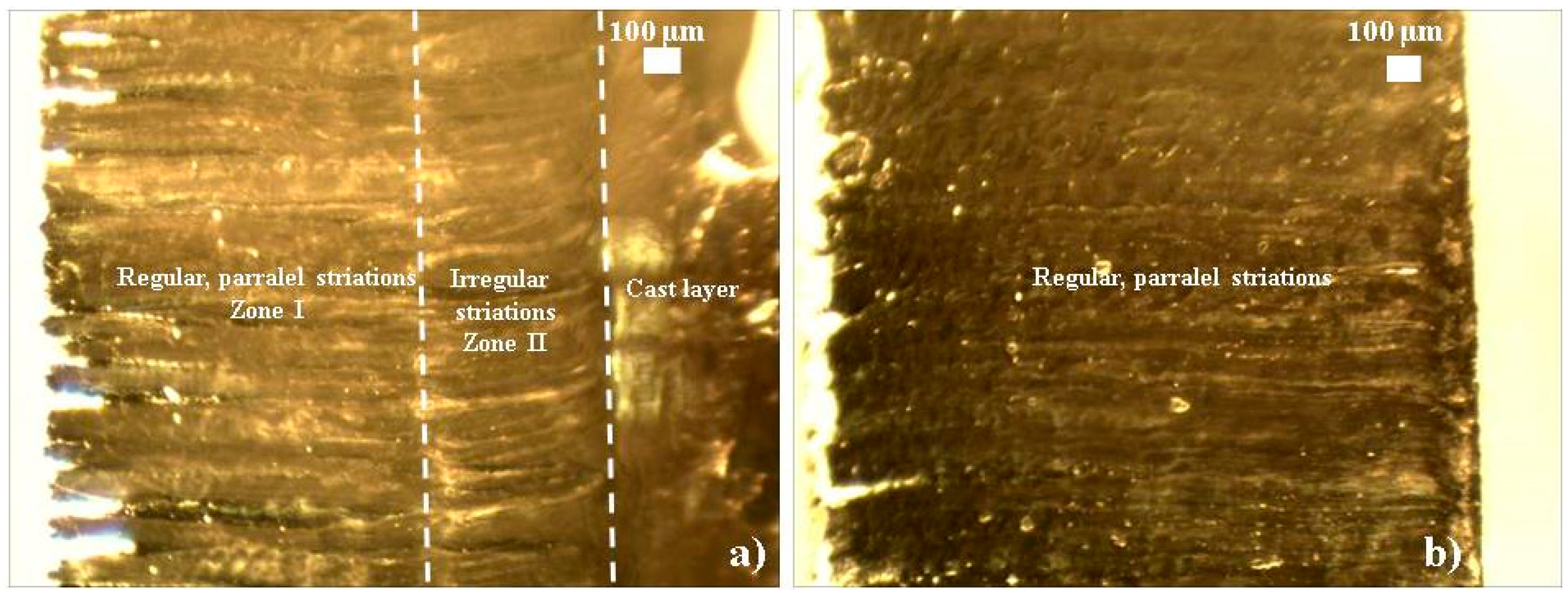

Cut surface of mild steel sheet cut using fibre laser with cutting speed.

While striation free cut could be realized in cutting of mild steel sheets of 1 3 mm thickness order with o 2 gas assist but not in other materials such as stainless steel or inert gas assisted.

A 30 mm s 1 b 55 mm s.