Typically low slope metal roof systems vary in weight from 40 to 135 pounds per 100 square feet making them among the lightest roofing products and the easiest to install.

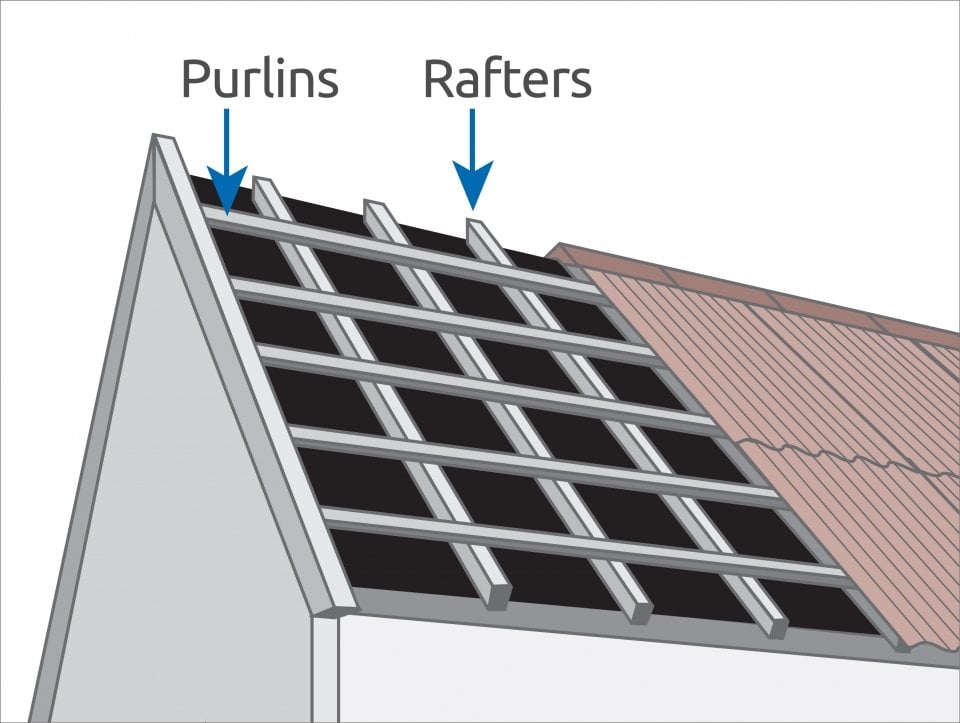

Square foot estimate of metal low slope roof on purlins.

Stone coated steel roof tiles.

The 1 inch variety is the best all purpose size.

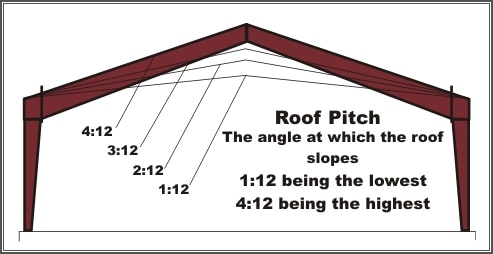

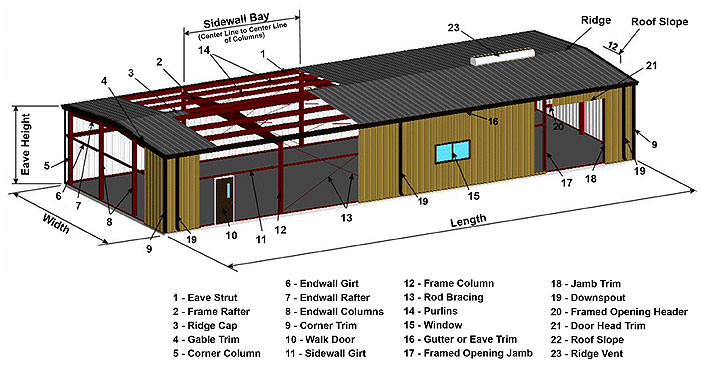

Roof slope style.

30 roofing squares x 80 screws 2 400 screws.

Get the square footage of roof and divide it by 100 and it will give the number of squares you need and for every decimal number over 3 buy a bundle to achieve the amount of material.

It is often compared to slope but is not exactly the same.

Steel roof deck 18 gauge corrugated.

Calculate the total linear feet for the roof for using both the 24 inch wide material and the 36 inch wide material.

There are two main categories of roofing.

Panels are often measured in inches use our inches to feet conversion calculator to convert to feet.

A roofing square is 100 square feet.

Conventional slope roof range between 4 in 12 and 8 in 12.

1square of roofing covers 100 square feet of roof a bundle is 1 3 of a square.

Divide 533 square feet by 2 feet and the result is 266 5 linear feet.

Screws are available in quantities of 250.

Western states metal roofing.

A low slope roof is anywhere from 2 in 12 to 4 in 12.

A lightweight roofing system also places fewer demands on a building s structural support system an important consideration in earthquake prone areas.

24 inches divided by 12 inches is equal to 2 feet and 36 inches divided by 12 inches is equal to 3 feet.

Finally divide the square footage of the roof by the square footage of the metal roofing panel to find the number of panels needed for your roof.

The table below can be used to figure approximate quantities of screws for various purlin spacings and sizes of roofs.

3 000 square feet x 80 2 400 screws.

Western states metal roofing.

Take your square footage and multiply it by 80.

Industrial metal supply company.

This will be followed by steel shingles at 7 2 7 5 per square foot.

On the low end you can install steel corrugated metal panels for about 4 5 6 per square foot includes labor and materials.

Stone coated metal roofs are more expensive 9 per square foot.

80 screws for each roofing square.

Steel roof deck 20 gauge corrugated.

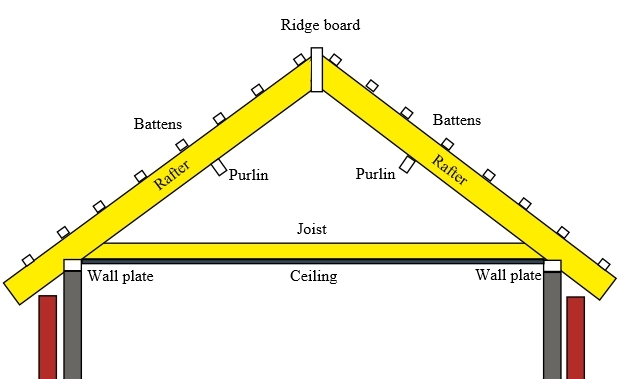

Roof pitch is the measurement of a roof s vertical rise divided by its horizontal run.

That is the roof s rise.

The run always remains constant at 12 inches.

Here are two easy formulas for determining the amount of metal roofing screws.

In the united states a run of 12 inches 1 foot is used and pitch is measured as the rise of the roof over 12 inches.

A flat roof has a slope of 2 in 12 or less.

Steel roof deck 22 gauge corrugated.

Allsteel carries screws in 2 different lengths.

Western states metal roofing.

Measure the length and width in feet then multiply together to find the square footage.